Do LS Contactors have mechanically linked contacts?

The short answer to this question is YES!

What are mechanically linked contacts?

Mechanically linked contacts (also known as positively driven contacts) are contacts—typically in control devices like contactors and auxiliary switches—where the opening and closing of normally open (NO) and normally closed (NC) contacts are physically connected in such a way that:

- Both cannot be closed at the same time.

- If one contact is welded or stuck (fails), the movement of the mechanism ensures the other contact can't move into a dangerous or misleading state.

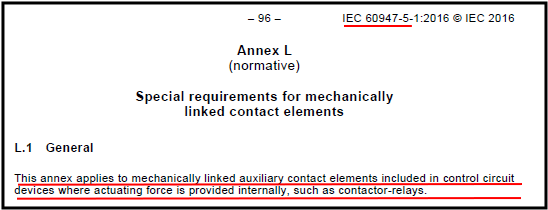

For contact elements to be labeled as mechanically linked, they must follow the special requirements under IEC 60947-5-1 Annex L

The requirements for this standard is in the powerpoint attached below named "Mechanically Linked Standards". In this powerpoint file you will find the terms, identifications, tests, etc that are required for contacts to meet to be classified as mechanically linked.

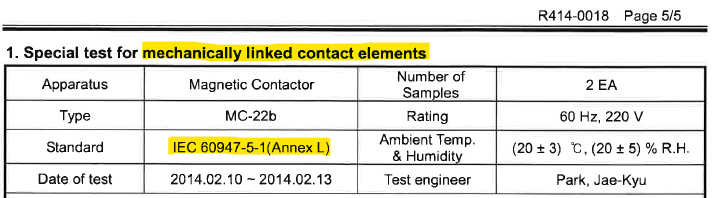

Our MC-22b has mechanically linked contact elements as you can see from the test report below. Because it passed the requirements for Standard: IEC 60947-5-1 Annex L, this means that this contactor has mechanically linked contacts.

Our MC-32a/40a also has mechanically linked contact elements as you can see from the test report below.

(The MC-32a and MC-40a have the same internal components but the difference is just the rated current: 32A vs 40A).

This product is slightly different from the MC-22b. The MC-22b has an auxiliary contact built into the main body, therefore, it is possible to conduct the IEC 60947-5-1 "Mechanically Linked Contact" test on the main unit itself. However, the MC-32a and 40a do not have built-in auxiliary contacts. To use auxiliary contacts with these models, an auxiliary contact unit called UA-1 must be attached to the MC-32a or 40a. Therefore, as previously sent, the test was conducted on the UA-1 with the MC-32a, and this serves as valid supporting documentation. As you may have guessed, the mechanically linked contact requirement pertains to the auxiliary contacts, not the main contacts.

Safety contactor (eng).pptx - Google Slides

The requirements for this standard is in the powerpoint attached below named "Mechanically Linked Standards". In this powerpoint file you will find the terms, identifications, tests, etc that are required for contacts to meet to be classified as mechanically linked.

Our MC-22b has mechanically linked contact elements as you can see from the test report below. Because it passed the requirements for Standard: IEC 60947-5-1 Annex L, this means that this contactor has mechanically linked contacts.

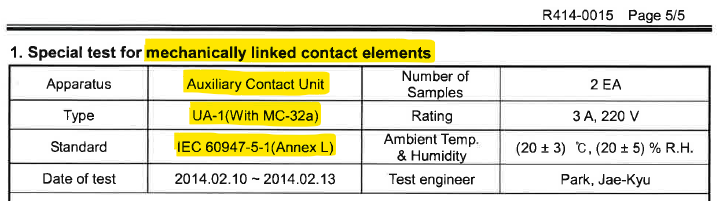

Our MC-32a/40a also has mechanically linked contact elements as you can see from the test report below.

(The MC-32a and MC-40a have the same internal components but the difference is just the rated current: 32A vs 40A).

This product is slightly different from the MC-22b. The MC-22b has an auxiliary contact built into the main body, therefore, it is possible to conduct the IEC 60947-5-1 "Mechanically Linked Contact" test on the main unit itself. However, the MC-32a and 40a do not have built-in auxiliary contacts. To use auxiliary contacts with these models, an auxiliary contact unit called UA-1 must be attached to the MC-32a or 40a. Therefore, as previously sent, the test was conducted on the UA-1 with the MC-32a, and this serves as valid supporting documentation. As you may have guessed, the mechanically linked contact requirement pertains to the auxiliary contacts, not the main contacts.

Safety contactor (eng).pptx - Google Slides